What does a flexible circuit board do?

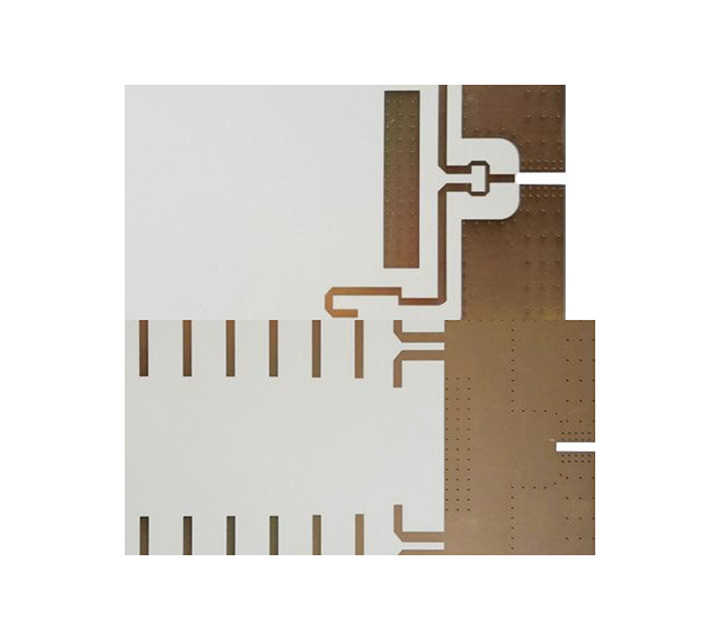

Flexible printed circuit boards consist of conductive metal strips, usually copper, insulated by a dielectric material or solder mask. The circuit board’s critical function is to carry electronic signals while providing mechanical flexing, enabling the use of smaller connectors and shielding radiated noise for EMI.

A flexible printed circuit board (FPC or FPCB) is a printed circuit board having a base material composed of polyester resin or polyimide resin. The flexible printed circuit board can be variously bent and folded according to the manufacturing needs of any particular application.

Flexible printed circuits offer a broad array of physical and electrical interconnect solutions that cannot be achieved with rigid printed circuit board solutions. At HSXpcb, we offer a comprehensive range of flexible circuit manufacturing and circuit board assembly.

The basic portion of a rigid flexible PCB is a film, which is used to support circuits composed of copper pieces. The various flexible pcb manufacturing process properties belonging to a flexible printed circuit board include: lightness, soft, thinness, smallness, ductility, flexibility, and high-wiring density. Accordingly, the flexible printed circuit board offers design freedom in electronic equipment, and in particular, saves an amount of wasted space, thereby downsizing the equipment. Therefore, the rigid flexible PCB is typically applied within tiny products, such as notebooks, mobile phones, personal digital assistants (PDAs) and information appliances (IA)

The Necessity of Using Flexible Circuit Board

The complexity of electronic components and switches is continually increasing nowadays and need faster signal flow rates. So, higher transmission frequencies are required. High-frequency PCBs help a lot when integrating special signal requirements into electronic components and products with advantages like high efficiency, and fast speed, lower attenuation, and constant dielectric properties.

High Frequency (HF) PCB is used to transmit electromagnetic waves in the frequency of GHz with minimal loses in the variety of applications, including mobile, microwave, radio frequency (RF) and high-speed design applications. Hence, printed circuit boards with some specific characteristics are used to transmit these electromagnetic waves. Several parameters are taken into considerations while designing a PCB for high frequency applications.

A high frequency PCB can meet your needs when incorporating a special signal requirement into your electronic devices and products. These higher transmission frequencies are capable of supporting the faster signal flow rates that are a necessity in today’s increasingly complex electronic switches and other components.

What are the constituent materials of FPC flexible circuit boards?

FPC flexible circuit board is one of the popular circuit board types to meet the needs of flexible electronic circuits. Designed to replace traditional wire harnesses, flexible circuit boards can meet a variety of complex electronic designs. Although the performance of flexible PCB depends on many factors, the main material plays a key role in it. So, what are the constituent materials of the FPC flexible circuit board? In the structure of FPC flexible circuit, the constituent materials are composed of flexible copper clad laminate (FCCL), cover film, adhesive film and so on.

- Flexible Copper Clad Laminate (FCCL): Common sheet films of flexible copper clad laminates include polyimide film (PI), polyester (PET), polyethylene naphthalate (PEN), liquid crystal display polymer ( LCP) and other polymer material plastic films. In the FPC flexible circuit board, the copper clad laminate mainly plays the role of three levels of conductivity, insulation layer and support point.

- Cover film: It is composed of chemical plastic film and adhesive. The function of the cover film is to protect the conductive part of the flexible circuit that has been completed. Adhesive films have different sheet film and adhesive types and thickness specifications.

- Adhesive film: It is formed by pouring adhesive on both sides or one side of a substrate film. There are also adhesive films with a pure adhesive layer without a substrate. The adhesive film has different adhesive types and thickness specifications. Adhesive film is used for interlayer bonding and insulation of multilayer boards. Ordinary FPC flexible circuit boards are mainly composed of two materials: base material + cover film. Let me talk about the base material first. The base material is mainly composed of PI or PET + glue + copper. PI is a polyimide insulating resin material, which is characterized by high temperature resistance. , good bending performance, good reliability of the products produced, more than 2 times the price of PET, is the main material of FPC flexible circuit boards, PET is polyester insulating resin material, the characteristics are just opposite to PI, and there are few general FPC manufacturers use.

Why Choose HSX

Top Flexible Circuit Board material resources, so that your products win at the root

The factory always has imported and domestic plates with dielectric constants ranging from 2.2 to 10.6

- High frequency materials: Rogers/Rogers, taconic/taikangli, Arlon, Isola, F4BM/Wangling, PTFE/Teflon, TP-2, etc., with dielectric constants ranging from 2.2 to 10.6.

- Rogers series: Rogers RO4350B, RO4003C, RT5880, RT5870, ro3003, ro3010, RO4730, RT6006, RT6010, etc.

Leading process capability to meet Flexible Circuit Board manufacturing needs

- Max. thickness to diameter ratio 10:1 Max. copper thickness 6OZ Max. working board size 2000x610mm

- The thinnest 4-layer board 0.33mm The smallest hole 0.10mm

- Minimum line width/line spacing 3mil/3mil

- Proven hybrid technology: ROGERS/Rogers+FR4,FR4+PTFE,FR4+408HR,ceramic+FR4 etc.

Experienced

- PCB Flexible Circuit Board samples + small and medium batch, more than ten years of experience, skilled in PCB Flexible Circuit Board expertise

- Products are: The power splitter, coupler, combiner, power amplifier, dry amplifier, base station, RF antenna, 4G antenna used in the high frequency circuit board has professional production experience

PCB acceptance criteria

- IPC-A-600G standard (PCB conformity standard);

- GJB326A-96(military standard);

- IPC-6018A (high frequency board acceptance standards)

- Implementation of quality PDCA cycle process, continuous improvement of product performance imported from the United States Diane ion chromatography tester (DIONEXICS-900) and temperature cycle inspection equipment to ensure high reliability and stability of the product.

Why Choose HSX

Top high-frequency material resources, so that your products win at the root

The factory always has imported and domestic plates with dielectric constants ranging from 2.2 to 10.6

- High frequency materials: Rogers/Rogers, taconic/taikangli, Arlon, Isola, F4BM/Wangling, PTFE/Teflon, TP-2, etc., with dielectric constants ranging from 2.2 to 10.6.

- Rogers series: Rogers RO4350B, RO4003C, RT5880, RT5870, ro3003, ro3010, RO4730, RT6006, RT6010, etc.

Leading process capability to meet high frequency PCB manufacturing needs

- Max. thickness to diameter ratio 10:1 Max. copper thickness 6OZ Max. working board size 2000x610mm

- The thinnest 4-layer board 0.33mm The smallest hole 0.10mm

- Minimum line width/line spacing 3mil/3mil

- Proven hybrid technology: ROGERS/Rogers+FR4,FR4+PTFE,FR4+408HR,ceramic+FR4 etc.

Experienced

PCB high-frequency board samples + small and medium batch, more than ten years of experience, skilled in PCB high-frequency board expertise

Products are: FR4 glass fiber board double-sided multilayer circuit board / high frequency board / high frequency circuit board / high frequency mixed laminate / mixed media laminate / F4B high frequency board / microwave RF board / high frequency microwave board, etc., the power splitter, coupler, combiner, power amplifier, dry amplifier, base station, RF antenna, 4G antenna used in the high frequency circuit board has professional production experience

PCB acceptance criteria

- IPC-A-600G standard (PCB conformity standard);

- GJB326A-96(military standard);

- IPC-6018A (high frequency board acceptance standards)

- Implementation of quality PDCA cycle process, continuous improvement of product performance imported from the United States Diane ion chromatography tester (DIONEXICS-900) and temperature cycle inspection equipment to ensure high reliability and stability of the product.

HSX’s High Frequency PCB Capabilities

Feature

Capability

Quality Grade

Standard IPC 2

Number of Layers

2- 6layers

Material

ROGERS, TACONIC, ARLON, FR4,

Board Size

Min 5mm x 5mm | Max 500mm x 745mm

Board Thickness

0.2mm – 4.0mm

Copper Weight(Finished)

0.5oz – 2oz

Min Tracing/Spacing

3mil/3mil

Solder Mask Color

Green, White, Blue, Black, Red, Yellow…

Silkscreen Color

White, Black, Yellow…

Surface Finish

Electroless nickel/immersion gold (ENIG) – RoHS

Immersion silver – RoHS

Immersion tin – RoHS

Min Annular Ring

0.1mm

Min Drilling Hole Diameter

0.15mm

Other Techniques

Peelable solder mask

Gold fingers

Carbon oil

Countersink holes

Do You Need Assistance or Have a Question?

We Provide Quality Service, Good Price for PCBs.

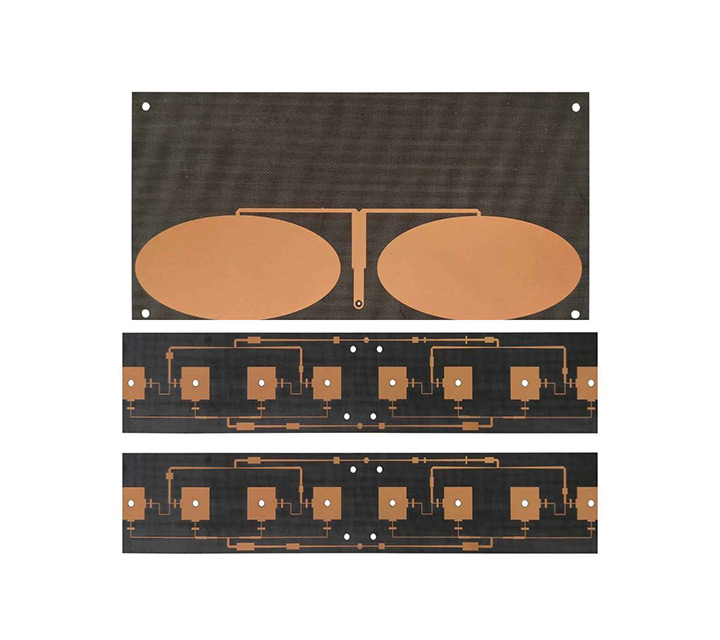

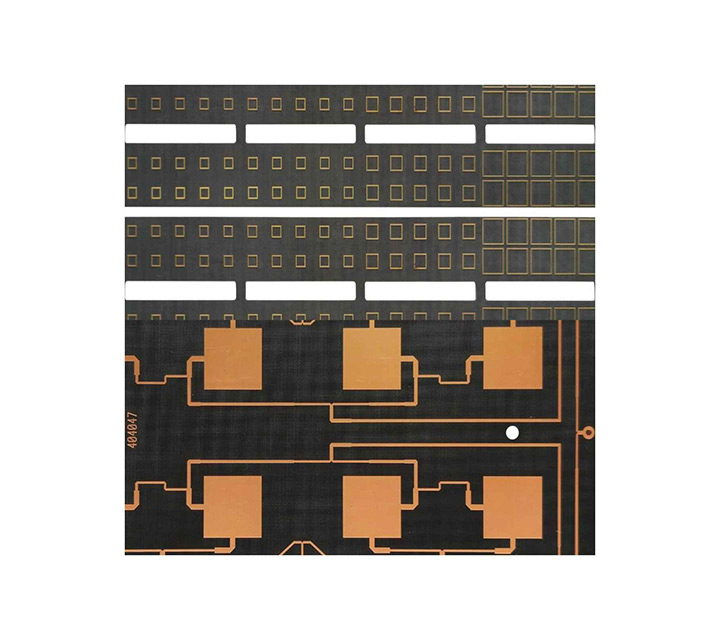

High Frequency PCB

Product Information

A high frequency printed circuit board, whether it’s rigid or flex, offers faster signal flow rates and a frequency range of up to 100 GHz. It’s important to note that there are numerous materials designed to operate at high frequency levels. HF PCBs are defined by lower dielectric constant (Dk), lower dissipation factor (Df), and low levels of thermal expansion. They are used regularly for HDI technology. They are also used extensively in high speed communications, telecommunications, and RF microwave technology.

Depending on the parameters, the HF signal is reflected on the circuit board, which means that the impedance (dynamic resistance) changes relative to the transmitting component. To avoid such capacitive effects, all parameters must be specified accurately and implemented with the highest level of process control.

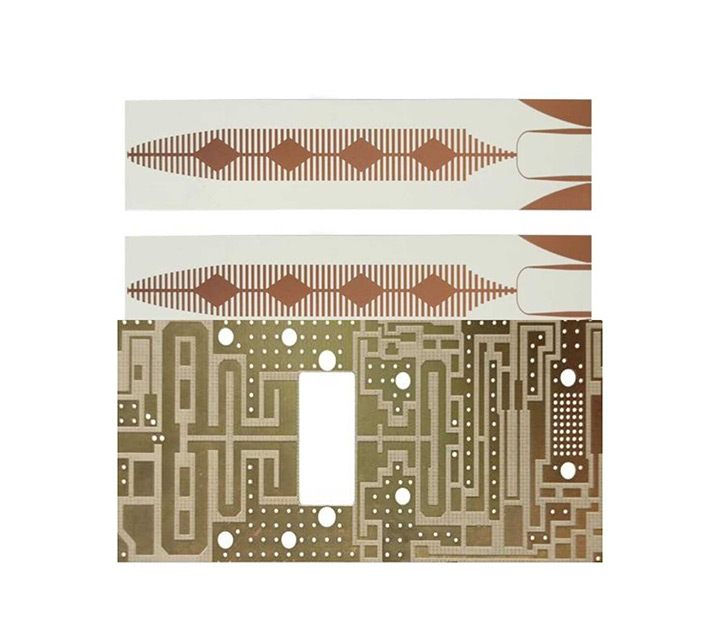

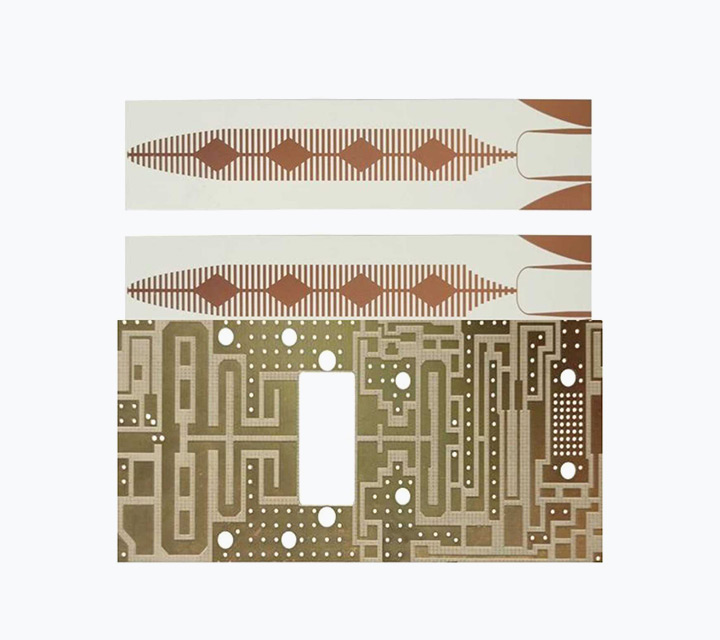

Applications for High Frequency PCB

High frequency printed circuit boardis are widely used for special signal transmission between objects. It operates from 500MHz to 2GHz and is right for mobile, microwave, RF and high-speed design applications. With the increasing complexity of electronic components and switches, faster signal flow and better transmission frequency are needed. High frequency PCB can play a really important role.Due to the short rise time of the pulse in electronic components, it is necessary to consider the conductor width as an electronic component in HF technology.

The Necessity of Using High Frequency PCB

High-frequency PCBs usually provide a frequency range from 500MHz to 2 GHz, which can meet the needs of high-speed PCB designs, microwave, radio frequency, and mobile applications. When the frequency is above 1 GHz, we can define it as high frequency.

- The complexity of electronic components and switches is continually increasing nowadays and need faster signal flow rates. So, higher transmission frequencies are required. High-frequency PCBs help a lot when integrating special signal requirements into electronic components and products with advantages like high efficiency, and fast speed, lower attenuation, and constant dielectric properties.

- High Frequency (HF) PCB is used to transmit electromagnetic waves in the frequency of GHz with minimal loses in the variety of applications, including mobile, microwave, radio frequency (RF) and high-speed design applications. Hence, printed circuit boards with some specific characteristics are used to transmit these electromagnetic waves. Several parameters are taken into considerations while designing a PCB for high frequency applications.

- A high frequency PCB can meet your needs when incorporating a special signal requirement into your electronic devices and products. These higher transmission frequencies are capable of supporting the faster signal flow rates that are a necessity in today’s increasingly complex electronic switches and other components.

Why Choose HSX

Top high-frequency material resources, so that your products win at the root

The factory always has imported and domestic plates with dielectric constants ranging from 2.2 to 10.6

- High frequency materials: Rogers/Rogers, taconic/taikangli, Arlon, Isola, F4BM/Wangling, PTFE/Teflon, TP-2, etc., with dielectric constants ranging from 2.2 to 10.6.

- Rogers series: Rogers RO4350B, RO4003C, RT5880, RT5870, ro3003, ro3010, RO4730, RT6006, RT6010, etc.

Leading process capability to meet high frequency PCB manufacturing needs

- Max. thickness to diameter ratio 10:1 Max. copper thickness 6OZ Max. working board size 2000x610mm

- The thinnest 4-layer board 0.33mm The smallest hole 0.10mm

- Minimum line width/line spacing 3mil/3mil

- Proven hybrid technology: ROGERS/Rogers+FR4,FR4+PTFE,FR4+408HR,ceramic+FR4 etc.

Experienced

- PCB high-frequency board samples + small and medium batch, more than ten years of experience, skilled in PCB high-frequency board expertise

- Products are: FR4 glass fiber board double-sided multilayer circuit board / high frequency board / high frequency circuit board / high frequency mixed laminate / mixed media laminate / F4B high frequency board / microwave RF board / high frequency microwave board, etc., the power splitter, coupler, combiner, power amplifier, dry amplifier, base station, RF antenna, 4G antenna used in the high frequency circuit board has professional production experience

PCB acceptance criteria

- IPC-A-600G standard (PCB conformity standard);

- GJB326A-96(military standard);

- IPC-6018A (high frequency board acceptance standards)

- Implementation of quality PDCA cycle process, continuous improvement of product performance imported from the United States Diane ion chromatography tester (DIONEXICS-900) and temperature cycle inspection equipment to ensure high reliability and stability of the product.

Why Choose HSX

Top high-frequency material resources, so that your products win at the root

The factory always has imported and domestic plates with dielectric constants ranging from 2.2 to 10.6

- High frequency materials: Rogers/Rogers, taconic/taikangli, Arlon, Isola, F4BM/Wangling, PTFE/Teflon, TP-2, etc., with dielectric constants ranging from 2.2 to 10.6.

- Rogers series: Rogers RO4350B, RO4003C, RT5880, RT5870, ro3003, ro3010, RO4730, RT6006, RT6010, etc.

Leading process capability to meet high frequency PCB manufacturing needs

- Max. thickness to diameter ratio 10:1 Max. copper thickness 6OZ Max. working board size 2000x610mm

- The thinnest 4-layer board 0.33mm The smallest hole 0.10mm

- Minimum line width/line spacing 3mil/3mil

- Proven hybrid technology: ROGERS/Rogers+FR4,FR4+PTFE,FR4+408HR,ceramic+FR4 etc.

Experienced

PCB high-frequency board samples + small and medium batch, more than ten years of experience, skilled in PCB high-frequency board expertise

Products are: FR4 glass fiber board double-sided multilayer circuit board / high frequency board / high frequency circuit board / high frequency mixed laminate / mixed media laminate / F4B high frequency board / microwave RF board / high frequency microwave board, etc., the power splitter, coupler, combiner, power amplifier, dry amplifier, base station, RF antenna, 4G antenna used in the high frequency circuit board has professional production experience

PCB acceptance criteria

- IPC-A-600G standard (PCB conformity standard);

- GJB326A-96(military standard);

- IPC-6018A (high frequency board acceptance standards)

- Implementation of quality PDCA cycle process, continuous improvement of product performance imported from the United States Diane ion chromatography tester (DIONEXICS-900) and temperature cycle inspection equipment to ensure high reliability and stability of the product.