Product Information

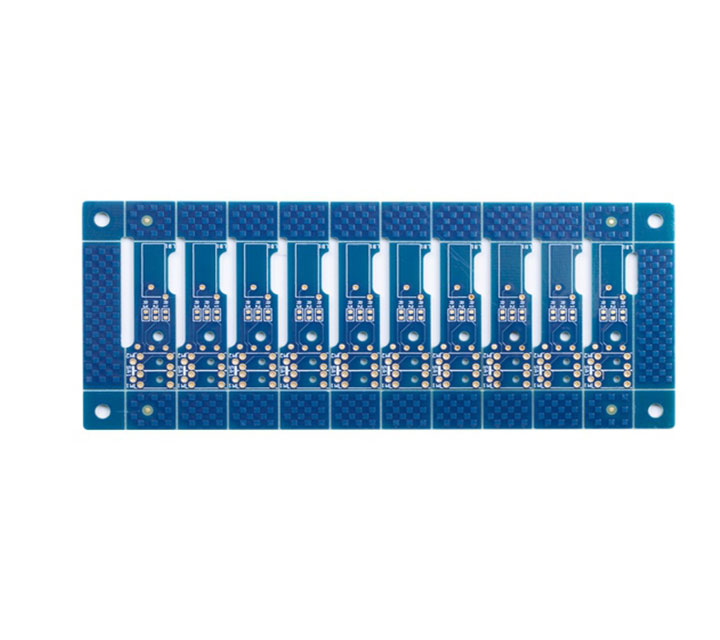

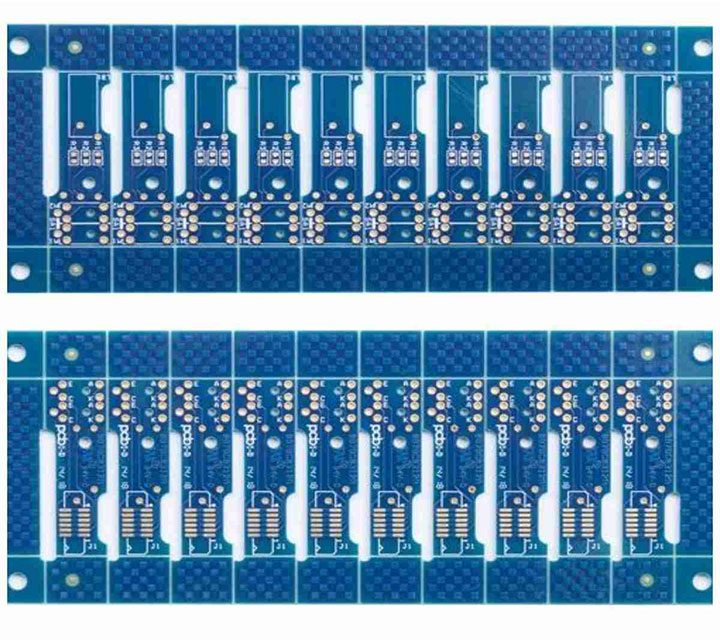

Quickturn PCB is a PCB made at the fastest speed, and it is referred to as PCB Quickturn in the industry.

PCB Quickturn is generally used to make prototypes, the quantity is not large, to seize time, to produce boards quickly and efficiently, and to use them for R&D testing by customers.

Normally, it takes about a week from the time you provide the gerber file to the PCB factory for proofing and receiving the samples. If you want an Quic, you only need to set 12 hours or 24 hours according to your own time. Of course, the price of allegro is also more expensive.

Information of PCB

Layers:1-32layer, if the layer is 20L or mare than 20L, will need to review the board.

The max finish panel size is 740* 500 MM, but if panel side >600 MM, will need to review it.

The Minimum panel size is 5 * 5mm.

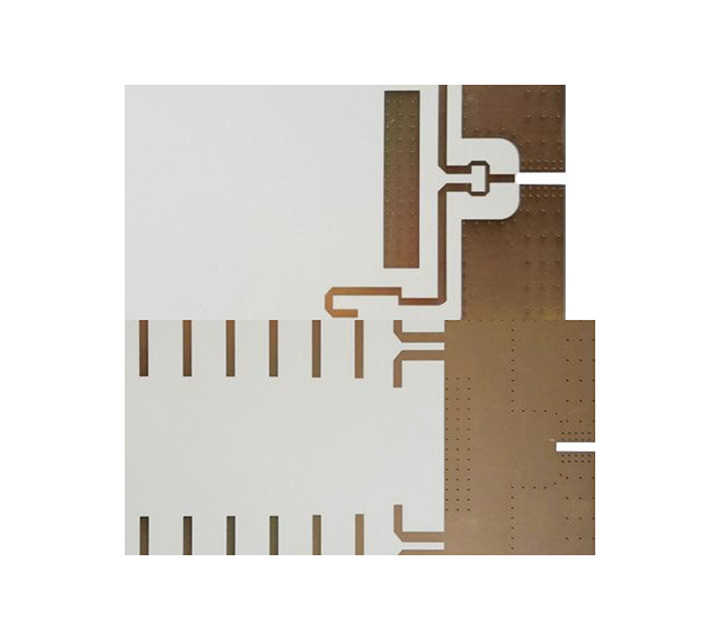

Raw materials of Printed circuit boards include FR4, Rogers, Halogen-free, High TG materials…

PCB thickness capability is from 0.2~4.0mm, if thickness less than 0.2 mm, or more than 4 mm, will needs to review.

PCB copper thickness capability is H~5oz. If more than 5oz, will need to review it at first.

Bow and twist tolerance is 0.075%.

The minimum hole size is 0.15mm, if drilling size is smaller than 0.15mm, will need to confirm the board at first.

The max hole size is 6.0mm, if hole size more than 6mm, will need to use milling to enlarge holes.

The color of printed circuit board include green, matt green,blue, matt blue, black, matt black, yellow, red, white, and so on.

The color of silkscreen color: include white, black and so on.

Printed circuit board surfaces include HASL lead free, ENIG, Immersion Sn, OSP, Selective ENIG + OSP, Immersion Silver, ENEPIG, Gold Finger,etc.

The Necessity of Quick Turn PCB

Quickturn PCB is generally used to make prototypes, the quantity is not large, and it takes time to quickly and efficiently produce boards for customers to do R&D testing.

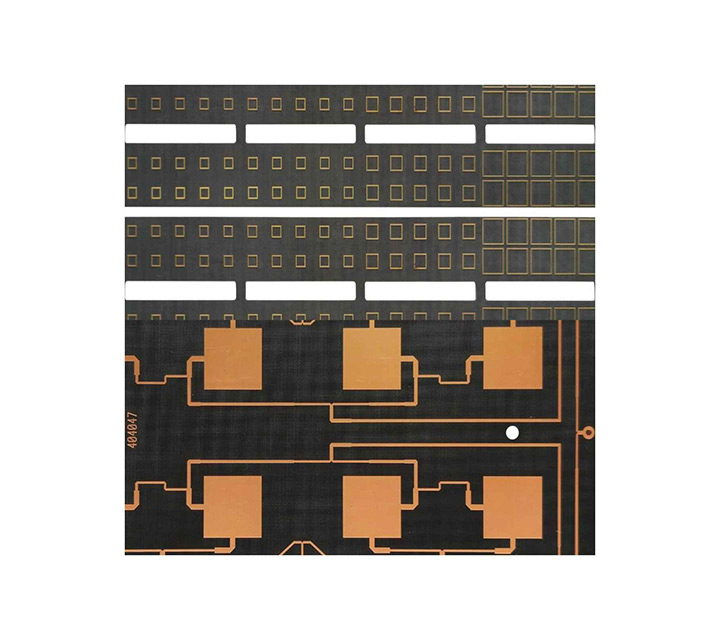

FR4 PCB

12-hour expedited delivery for single/double-layer board proofing,

24-hour expedited shipment of four/six-layer boards,

PCB small batches are shipped within three days, and the on-time delivery rate of products is as high as 99%;

1~14 layer board can be customized, the minimum line width and line spacing is 4/4mil, the minimum via hole is 8mil, the double layer board can be made of 2oz, 3oz, 4oz, 5oz, 10oz, and the fourth and sixth layers can be made of 2oz copper thickness;

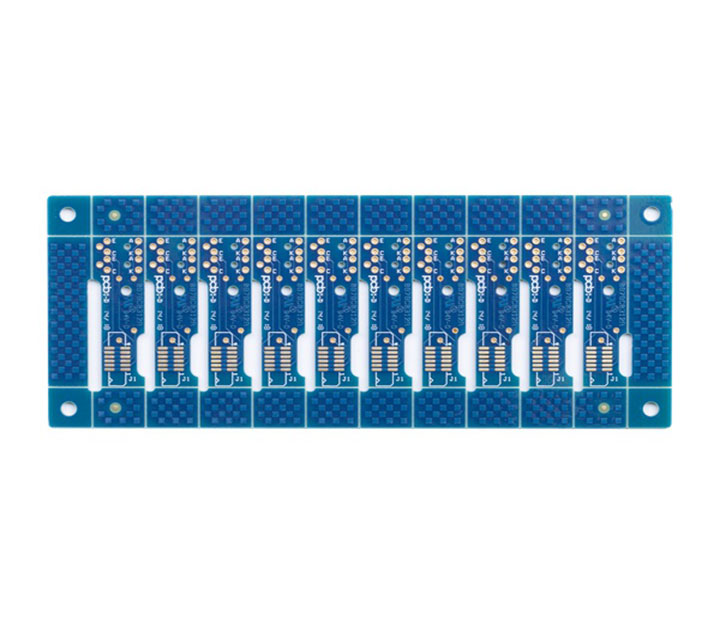

Rigid-Flexiable PCB

Urgent delivery within 12 hours at the fastest, order on the same day, delivery on the same day, faster than the same industry; support single-sided/double-sided; minimum finished product size: 5*5mm; maximum finished product size 120*50mm; board thickness: 2.0mm; Minimum via hole diameter: 0.2mm; Copper foil thickness: 10/10oz; Minimum line width/line spacing: 4mil/4mil; Via plug oil;

Why Choose HSX

Quick Turn PCB serives:

We can support customers with Quick turn PCB for many kinds of PCB. Such as

FR-4 PCB board;High-frequency PCB board;Copper based PCB board,Rigid-Flexiable PCB and etc.

Leading process capability to meet Quick Turn PCB manufacturing needs

- Max. thickness to diameter ratio 10:1 Max. copper thickness 6OZ Max. working board size 2000x610mm

- The thinnest 4-layer board 0.33mm The smallest hole 0.10mm

- Minimum line width/line spacing 3mil/3mil

- Such as FR-4 PCB board;High-frequency PCB board;Copper based PCB board,Rigid-Flexiable PCB and etc.

Experienced

- We can support customers with Quick turn PCB for many kinds of PCB. Such as

FR-4 PCB board;High-frequency PCB board;Copper based PCB board,Rigid-Flexiable PCB and etc.

Urgent delivery within 12 ~24 hours at the fastest, order on the same day, delivery on the same day, faster than the same industry.

PCB acceptance criteria

- IPC-A-600G standard (PCB conformity standard);

- GJB326A-96(military standard);

- IPC-6018A (high frequency board acceptance standards)

- Implementation of quality PDCA cycle process, continuous improvement of product performance imported from the United States Diane ion chromatography tester (DIONEXICS-900) and temperature cycle inspection equipment to ensure high reliability and stability of the product.

Why Choose HSX

Top high-frequency material resources, so that your products win at the root

The factory always has imported and domestic plates with dielectric constants ranging from 2.2 to 10.6

- High frequency materials: Rogers/Rogers, taconic/taikangli, Arlon, Isola, F4BM/Wangling, PTFE/Teflon, TP-2, etc., with dielectric constants ranging from 2.2 to 10.6.

- Rogers series: Rogers RO4350B, RO4003C, RT5880, RT5870, ro3003, ro3010, RO4730, RT6006, RT6010, etc.

Leading process capability to meet high frequency PCB manufacturing needs

- Max. thickness to diameter ratio 10:1 Max. copper thickness 6OZ Max. working board size 2000x610mm

- The thinnest 4-layer board 0.33mm The smallest hole 0.10mm

- Minimum line width/line spacing 3mil/3mil

- Proven hybrid technology: ROGERS/Rogers+FR4,FR4+PTFE,FR4+408HR,ceramic+FR4 etc.

Experienced

PCB high-frequency board samples + small and medium batch, more than ten years of experience, skilled in PCB high-frequency board expertise

Products are: FR4 glass fiber board double-sided multilayer circuit board / high frequency board / high frequency circuit board / high frequency mixed laminate / mixed media laminate / F4B high frequency board / microwave RF board / high frequency microwave board, etc., the power splitter, coupler, combiner, power amplifier, dry amplifier, base station, RF antenna, 4G antenna used in the high frequency circuit board has professional production experience

PCB acceptance criteria

- IPC-A-600G standard (PCB conformity standard);

- GJB326A-96(military standard);

- IPC-6018A (high frequency board acceptance standards)

- Implementation of quality PDCA cycle process, continuous improvement of product performance imported from the United States Diane ion chromatography tester (DIONEXICS-900) and temperature cycle inspection equipment to ensure high reliability and stability of the product.

HSX’s Quick Turn PCB Capabilities

Feature

Capability

Quality Grade

Standard IPC 2

Number of Layers

2- 24layers

Material

FR-4 PCB board;High-frequency PCB board;Copper based PCB board,Rigid-Flexiable PCB and etc.

Board Size

Min 5mm x 5mm | Max 500mm x 745mm

Board Thickness

0.2mm – 4.0mm

Copper Weight(Finished)

0.5oz – 2oz

Min Tracing/Spacing

3mil/3mil

Solder Mask Color

Green, White, Blue, Black, Red, Yellow…

Silkscreen Color

White, Black, Yellow…

Surface Finish

Electroless nickel/immersion gold (ENIG) – RoHS

Immersion silver – RoHS

Immersion tin – RoHS

Min Annular Ring

0.1mm

Min Drilling Hole Diameter

0.15mm

Other Techniques

Peelable solder mask

Gold fingers

Carbon oil

Countersink holes

Do You Need Assistance or Have a Question?

We Provide Quality Service, Good Price for PCBs.

Quick Turn PCB

Product Information

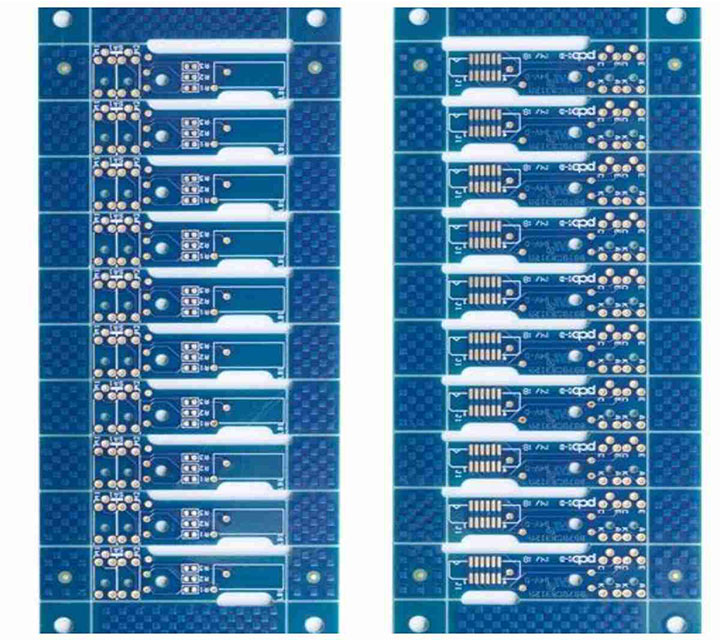

FR4 PCB

12-hour expedited delivery for single/double-layer board proofing,

24-hour expedited shipment of four/six-layer boards,

PCB small batches are shipped within three days, and the on-time delivery rate of products is as high as 99%;

1~14 layer board can be customized, the minimum line width and line spacing is 4/4mil, the minimum via hole is 8mil, the double layer board can be made of 2oz, 3oz, 4oz, 5oz, 10oz, and the fourth and sixth layers can be made of 2oz copper thickness;

Rigid-Flexiable PCB

Urgent delivery within 12 hours at the fastest, order on the same day, delivery on the same day, faster than the same industry; support single-sided/double-sided; minimum finished product size: 5*5mm; maximum finished product size 120*50mm; board thickness: 2.0mm; Minimum via hole diameter: 0.2mm; Copper foil thickness: 10/10oz; Minimum line width/line spacing: 4mil/4mil; Via plug oil;

We can support customers with Quick Turn PCB for many kinds of PCB.

Such as

FR-4 PCB board;High-frequency PCB board;Copper based PCB board,Rigid-Flexiable PCB and etc.

Urgent delivery within 12 ~24 hours at the fastest, order on the same day, delivery on the same day, faster than the same industry

Applications for Quick Turn PCB

Quick Turn PCB is generally used to make prototypes, the quantity is not large, to seize time, to quickly and efficiently produce boards, and to use them for R&D testing by customers. Normally, it takes about a week from the time you provide the materials to the PCB factory for proofing to the time you receive the samples. If you want to Quick Turn PCB, you only need to set 12 hours or 24 hours according to your own time, of course, the price of Quick Turn PCB is also more expensive.

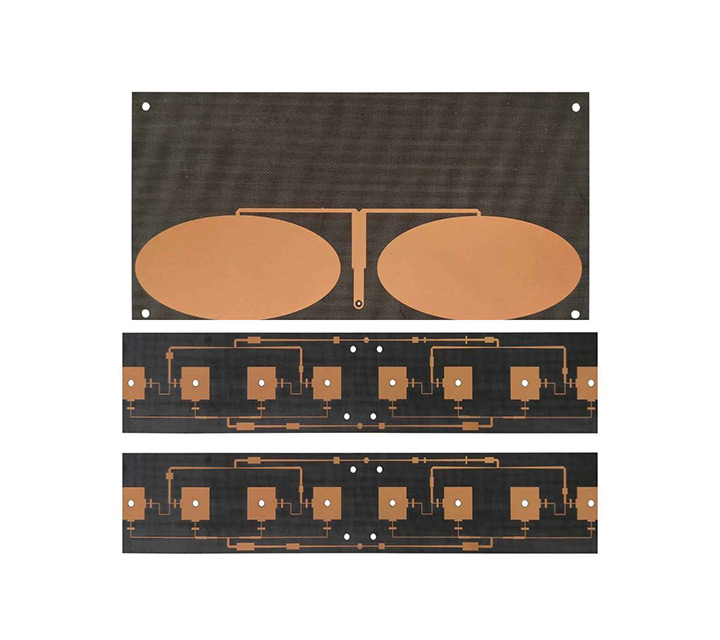

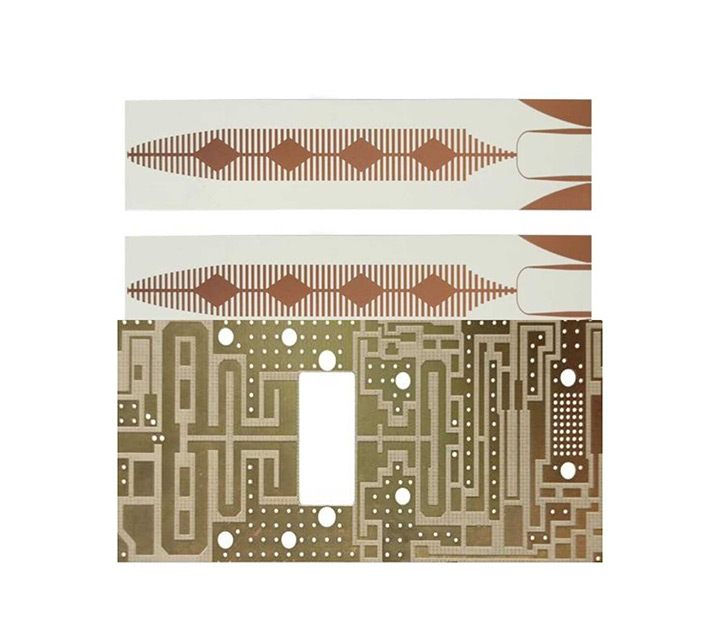

The Necessity of Using High Frequency PCB

High-frequency PCBs usually provide a frequency range from 500MHz to 2 GHz, which can meet the needs of high-speed PCB designs, microwave, radio frequency, and mobile applications. When the frequency is above 1 GHz, we can define it as high frequency.

FR4 PCB

12-hour expedited delivery for single/double-layer board proofing,

24-hour expedited shipment of four/six-layer boards,

PCB small batches are shipped within three days, and the on-time delivery rate of products is as high as 99%;

1~14 layer board can be customized, the minimum line width and line spacing is 4/4mil, the minimum via hole is 8mil, the double layer board can be made of 2oz, 3oz, 4oz, 5oz, 10oz, and the fourth and sixth layers can be made of 2oz copper thickness;

Rigid-Flexiable PCB

Urgent delivery within 12 hours at the fastest, order on the same day, delivery on the same day, faster than the same industry; support single-sided/double-sided; minimum finished product size: 5*5mm; maximum finished product size 120*50mm; board thickness: 2.0mm; Minimum via hole diameter: 0.2mm; Copper foil thickness: 10/10oz; Minimum line width/line spacing: 4mil/4mil; Via plug oil;

We can support customers with Quick Turn PCB for many kinds of PCB. Such as

FR-4 PCB board;High-frequency PCB board;Copper based PCB board,Rigid-Flexiable PCB and etc.

Urgent delivery within 12 ~24 hours at the fastest, order on the same day, delivery on the same day, faster than the same industry

Why Choose HSX

Top high-frequency material resources, so that your products win at the root

The factory always has imported and domestic plates with dielectric constants ranging from 2.2 to 10.6

- High frequency materials: Rogers/Rogers, taconic/taikangli, Arlon, Isola, F4BM/Wangling, PTFE/Teflon, TP-2, etc., with dielectric constants ranging from 2.2 to 10.6.

- Rogers series: Rogers RO4350B, RO4003C, RT5880, RT5870, ro3003, ro3010, RO4730, RT6006, RT6010, etc.

Leading process capability to meet high frequency PCB manufacturing needs

- Max. thickness to diameter ratio 10:1 Max. copper thickness 6OZ Max. working board size 2000x610mm

- The thinnest 4-layer board 0.33mm The smallest hole 0.10mm

- Minimum line width/line spacing 3mil/3mil

- Proven hybrid technology: ROGERS/Rogers+FR4,FR4+PTFE,FR4+408HR,ceramic+FR4 etc.

Experienced

- PCB high-frequency board samples + small and medium batch, more than ten years of experience, skilled in PCB high-frequency board expertise

- Products are: FR4 glass fiber board double-sided multilayer circuit board / high frequency board / high frequency circuit board / high frequency mixed laminate / mixed media laminate / F4B high frequency board / microwave RF board / high frequency microwave board, etc., the power splitter, coupler, combiner, power amplifier, dry amplifier, base station, RF antenna, 4G antenna used in the high frequency circuit board has professional production experience

PCB acceptance criteria

- IPC-A-600G standard (PCB conformity standard);

- GJB326A-96(military standard);

- IPC-6018A (high frequency board acceptance standards)

- Implementation of quality PDCA cycle process, continuous improvement of product performance imported from the United States Diane ion chromatography tester (DIONEXICS-900) and temperature cycle inspection equipment to ensure high reliability and stability of the product.

Why Choose HSX

Top high-frequency material resources, so that your products win at the root

The factory always has imported and domestic plates with dielectric constants ranging from 2.2 to 10.6

- High frequency materials: Rogers/Rogers, taconic/taikangli, Arlon, Isola, F4BM/Wangling, PTFE/Teflon, TP-2, etc., with dielectric constants ranging from 2.2 to 10.6.

- Rogers series: Rogers RO4350B, RO4003C, RT5880, RT5870, ro3003, ro3010, RO4730, RT6006, RT6010, etc.

Leading process capability to meet high frequency PCB manufacturing needs

- Max. thickness to diameter ratio 10:1 Max. copper thickness 6OZ Max. working board size 2000x610mm

- The thinnest 4-layer board 0.33mm The smallest hole 0.10mm

- Minimum line width/line spacing 3mil/3mil

- Proven hybrid technology: ROGERS/Rogers+FR4,FR4+PTFE,FR4+408HR,ceramic+FR4 etc.

Experienced

PCB high-frequency board samples + small and medium batch, more than ten years of experience, skilled in PCB high-frequency board expertise

Products are: FR4 glass fiber board double-sided multilayer circuit board / high frequency board / high frequency circuit board / high frequency mixed laminate / mixed media laminate / F4B high frequency board / microwave RF board / high frequency microwave board, etc., the power splitter, coupler, combiner, power amplifier, dry amplifier, base station, RF antenna, 4G antenna used in the high frequency circuit board has professional production experience

PCB acceptance criteria

- IPC-A-600G standard (PCB conformity standard);

- GJB326A-96(military standard);

- IPC-6018A (high frequency board acceptance standards)

- Implementation of quality PDCA cycle process, continuous improvement of product performance imported from the United States Diane ion chromatography tester (DIONEXICS-900) and temperature cycle inspection equipment to ensure high reliability and stability of the product.