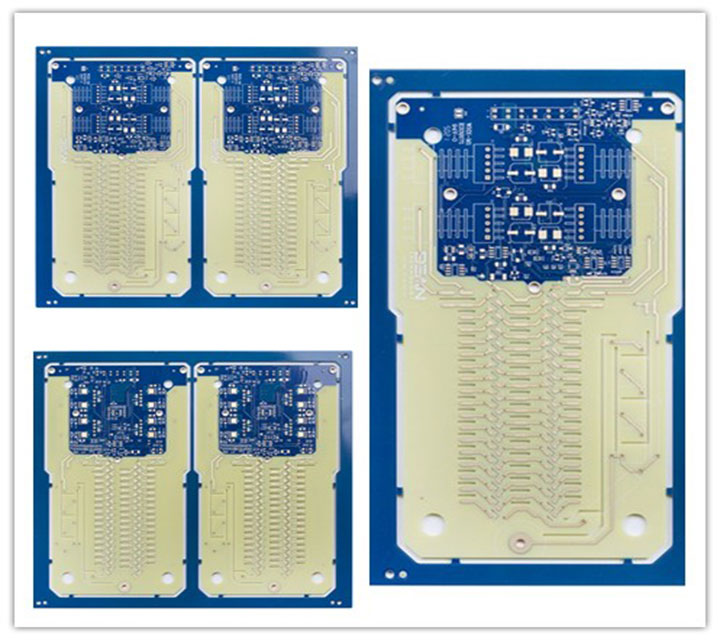

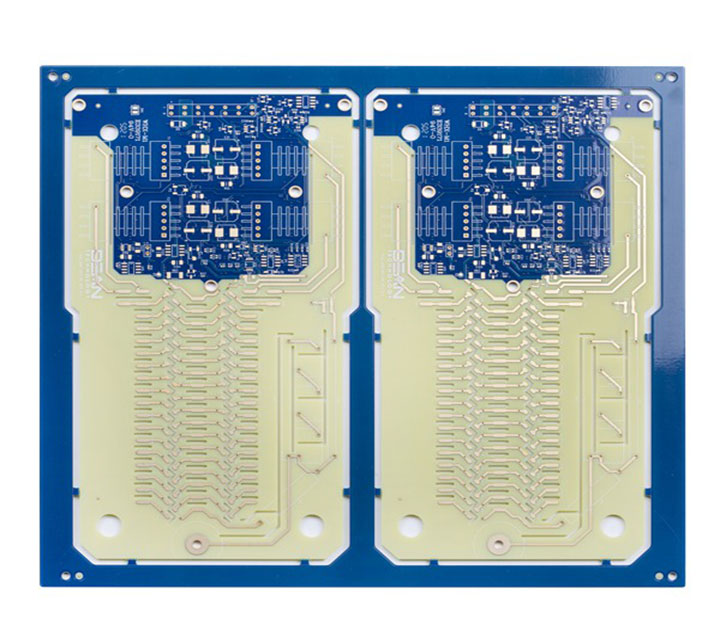

Product Information

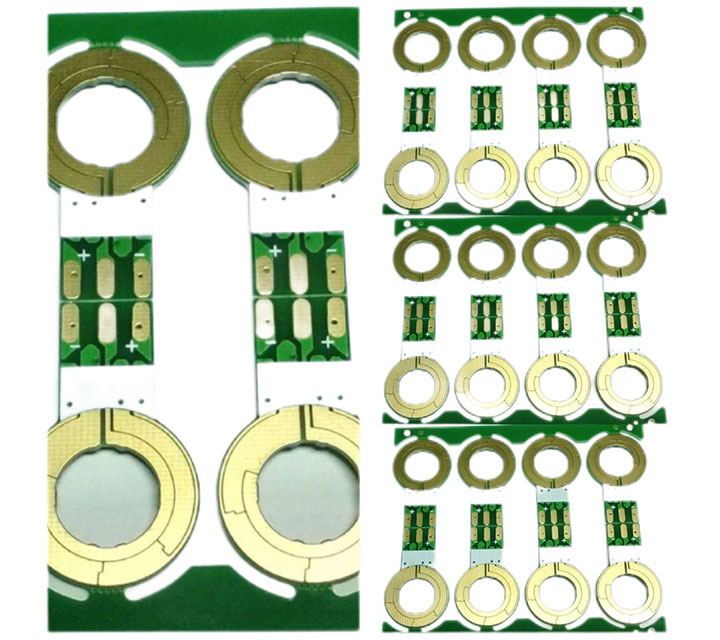

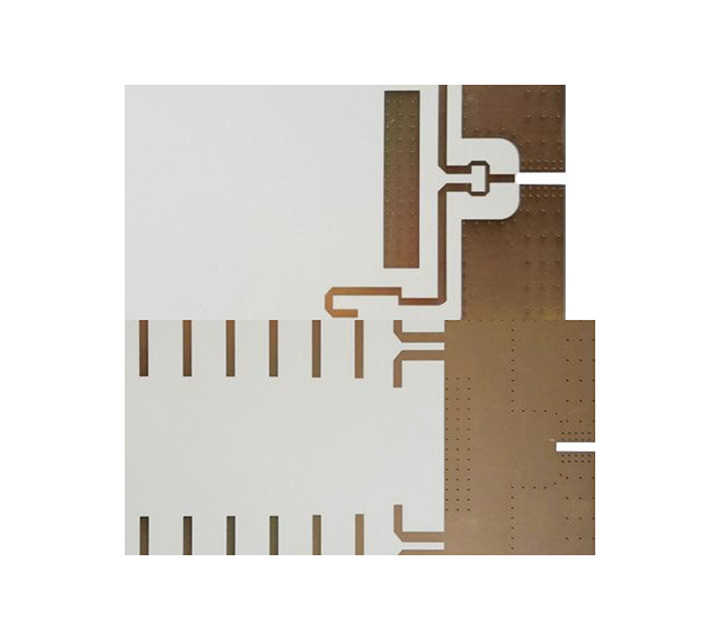

Rigid PCBs’ applications range from small electrical devices to large aerospace, military and medical fields. And flex printed circuit boards are built of flexible substrate. They have lower thickness, lighter weight, and they are dynamically bendable, so they can save space They also have equally vast applications because of their excellent electrical and thermal performance.

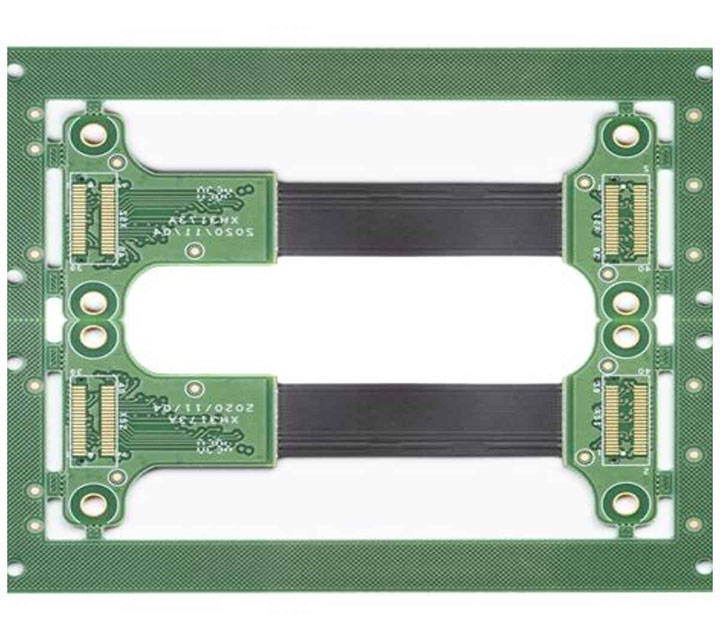

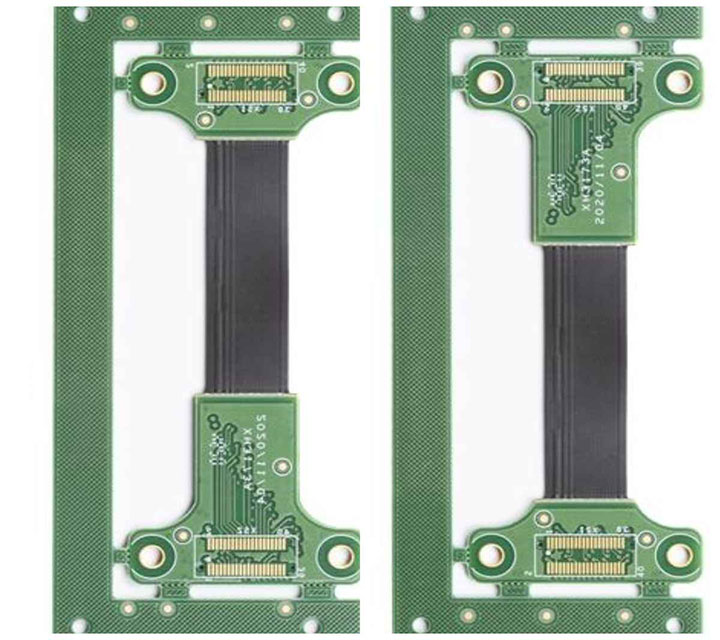

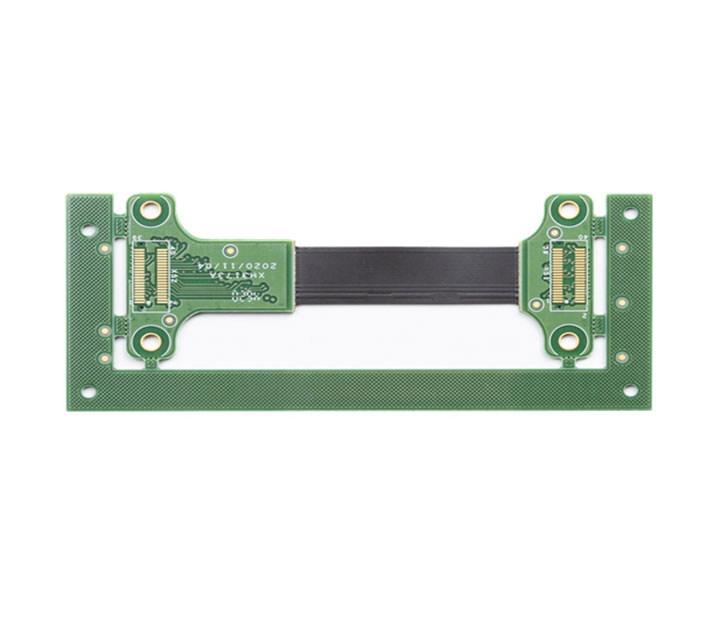

Flex-rigid PCBS are boards which combile the technology of flexible board and rigid board. They consist of multiple layers of flexible circuit substrates attached to one or more rigid boards either externally or internally. Therefore they own the advantages of both rigid printed circuit boards and flex circuit boards. Rigid-Flex products provide reliable integration of multiple rigid printed circuit board assemblies into a single PCB module capable of supporting assembly, space/weight savings, and mechanical stability.

Why Use Rigid-Flex PCB?

Rigid-flex board has both the characteristics of FPC and PCB. Therefore, it can be used in some products with special requirements. It has both a certain flexible area and a certain rigid area, which saves the internal space of the product and reduces the The volume of the finished product is of great help to improve the performance of the product. Disadvantages: There are many production processes of soft and hard boards, the production is difficult, the yield rate is low, and more materials and manpower are invested. Therefore, its price is relatively expensive and the production cycle is relatively long.

What are the performance and advantages of Rigid Flex PCB?

With its excellent physical properties, the rigid-flex board will surely shine in the near future. Advantages: It has excellent characteristics of both PCB and FPC. It can be folded and bent in half to reduce space, and it can also weld complex components. At the same time, it has a longer life than the cable, more reliable stability, and is not easy to break and oxidize and fall off. It is very helpful to improve product performance.

- Reliability: Rigid-flex board can solve the problem of FPC installation reliability.

The FPC is connected through a connector, which brings installation cost, inconvenient installation, installation reliability problems, and easy short circuit, falling off and other problems. In the design of a large-scale shipment of Hikvision, we saw the phenomenon of repairing the FPC and PCB after the FPC is installed. The rigid-flex board solves the problem of FPC installation reliability.

- Improve production efficiency

Although the price per unit area of the rigid-flex board has increased, it saves the cost of the connector, reduces the installation time, reduces the repair rate, improves the manufacturability and reliability. The use of products shipped in large quantities is often effective in reducing costs.

- Effectively improve signal quality

Since there is no connection through the connector, the trace continuity is better and the signal integrity is better. The traditional IPC uses FPC and connectors to connect the Sensor (video sensor) board and the main control board. The main control board and the sensor board can be integrated by using the rigid-flex board, which solves many problems and meets the structural design requirements of the cylinder machine.

Why Choose HSX

Top Rigid-flex board material resources, so that your products win at the root

1) ruducing products’ weight

2) temperature resistance is excellent

3) being more flexible

4) with good reliability

Leading process capability to meet Rigid flex PCB manufacturing needs

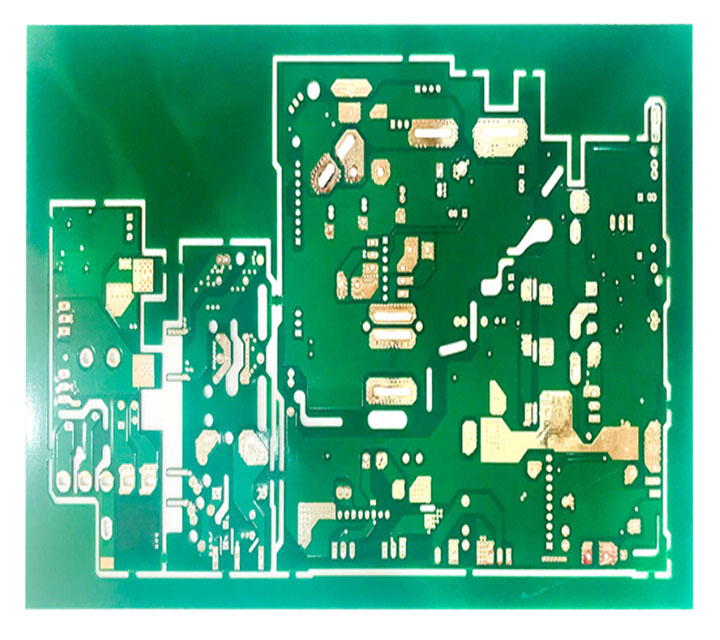

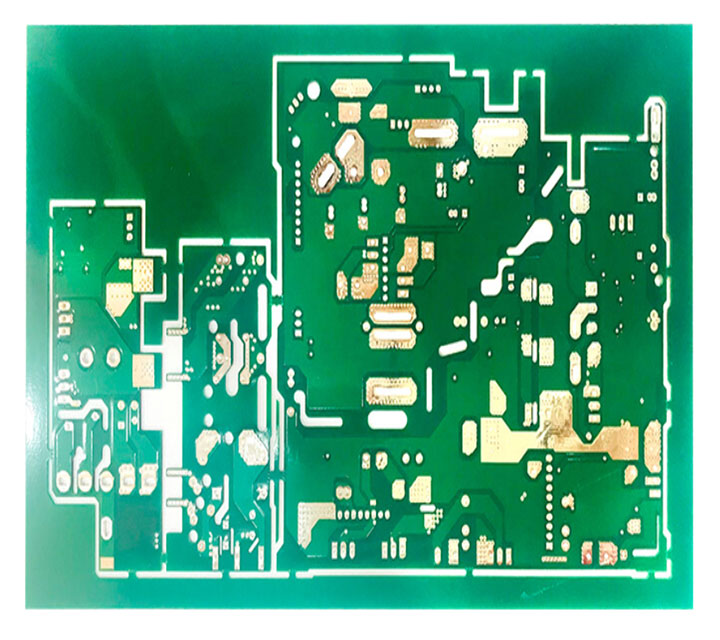

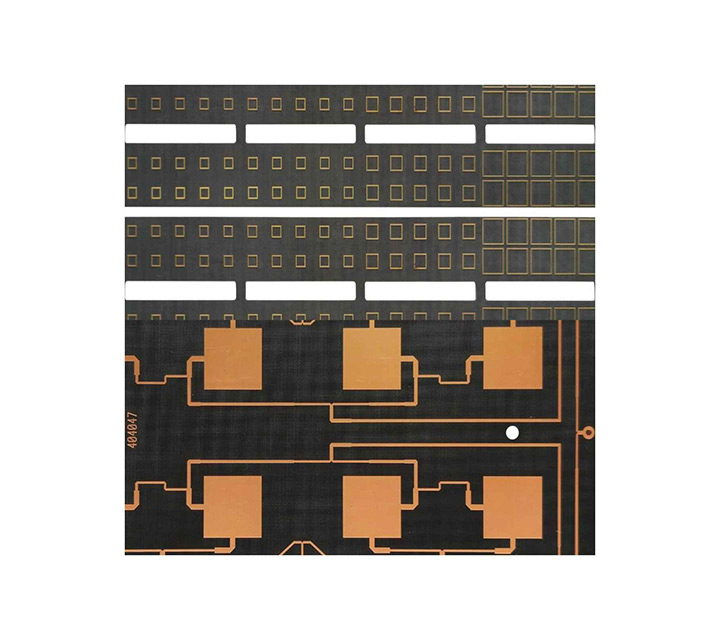

- A rigid flex PCB combines a hard board and a flexible circuit board. The manufacturing process include traditional rigid boards and flexible circuit. Some layers are flexible circuits that run through the hard boards. The board fabricator attaches PTH to connect layers of rigid boards to areas of the flexible circuit.

- Rigid flex PCB is a hybrid of a Rigid PCB and a Flex PCB. Rigid-flex printed circuit board owns the characteristics of flexible PCB and rigid PCB ate the same time. So it can be applied to various high-technology fields, like automotive product, vehicle product, commucation production, consumer electronic product, telecommunication production and so on.

- Weight reduction, more valuable component assembly and wiring space, reduced logistical complexity, simplification of assembly, considerably improved reliability of the entire PCB system, remarkable improvement of functional testability

Experienced

- Rigid flex PCB are rigid boards using a combination of flexible and rigid board technology in one application. It combines various rigid and flexible technologies that make up a very diverse and effective combination . It can absorb much heat, and make for a tiny and compact circuit that can be as effective as bigger circuits. So they are specifically designed for use in high-performance and high-speed applications, like telecommunication systems, aerospace equipment,automotive devices,military equipment,consumer appliances and so on.

Advantage:

- Higher circuit density

- Decreased Assembly Time and Costs.

- Increased Heat Dissipation

- A multi-layer flex circuit combines several single-sided or double-sided circuits with complex interconnections, shielding and/or surface mounted technologies in a multi-layer design.

- Several copper layers separated encapsulated by dielectric layers. Metal layers are often connected by metalized thru-holes

- The surface treatment is mostly ENIG, but it is acceptable for Plating Nickel-Gold, Plating Tin, Immersion Tin and OSP.

- The multilayers may or may not be continuously laminated together throughout the production process. If your design needs require maximum flexibility, continuous lamination may not be appropriate.

Why Choose HSX

Top high-frequency material resources, so that your products win at the root

The factory always has imported and domestic plates with dielectric constants ranging from 2.2 to 10.6

- High frequency materials: Rogers/Rogers, taconic/taikangli, Arlon, Isola, F4BM/Wangling, PTFE/Teflon, TP-2, etc., with dielectric constants ranging from 2.2 to 10.6.

- Rogers series: Rogers RO4350B, RO4003C, RT5880, RT5870, ro3003, ro3010, RO4730, RT6006, RT6010, etc.

Leading process capability to meet high frequency PCB manufacturing needs

- Max. thickness to diameter ratio 10:1 Max. copper thickness 6OZ Max. working board size 2000x610mm

- The thinnest 4-layer board 0.33mm The smallest hole 0.10mm

- Minimum line width/line spacing 3mil/3mil

- Proven hybrid technology: ROGERS/Rogers+FR4,FR4+PTFE,FR4+408HR,ceramic+FR4 etc.

Experienced

PCB high-frequency board samples + small and medium batch, more than ten years of experience, skilled in PCB high-frequency board expertise

Products are: FR4 glass fiber board double-sided multilayer circuit board / high frequency board / high frequency circuit board / high frequency mixed laminate / mixed media laminate / F4B high frequency board / microwave RF board / high frequency microwave board, etc., the power splitter, coupler, combiner, power amplifier, dry amplifier, base station, RF antenna, 4G antenna used in the high frequency circuit board has professional production experience

PCB acceptance criteria

- IPC-A-600G standard (PCB conformity standard);

- GJB326A-96(military standard);

- IPC-6018A (high frequency board acceptance standards)

- Implementation of quality PDCA cycle process, continuous improvement of product performance imported from the United States Diane ion chromatography tester (DIONEXICS-900) and temperature cycle inspection equipment to ensure high reliability and stability of the product.

HSX’s Rigid flex PCB Capabilities

Feature

Capability

Quality Grade

Standard IPC 2

Number of Layers

2- 24layers

Material

ROGERS, TACONIC, ARLON, FR4,

Board Size

Min 5mm x 5mm | Max 500mm x 745mm

Board Thickness

0.2mm – 4.0mm

Copper Weight(Finished)

0.5oz – 2oz

Min Tracing/Spacing

3mil/3mil

Solder Mask Color

Green, White, Blue, Black, Red, Yellow…

Silkscreen Color

White, Black, Yellow…

Surface Finish

Electroless nickel/immersion gold (ENIG) – RoHS

Immersion silver – RoHS

Immersion tin – RoHS

Min Annular Ring

0.1mm

Min Drilling Hole Diameter

0.15mm

Other Techniques

Peelable solder mask

Gold fingers

Carbon oil

Countersink holes

Do You Need Assistance or Have a Question?

We Provide Quality Service, Good Price for PCBs.

Rigid-flex PCB

Product Information

Rigid-flex PCB is a layer of copper foil bonded on the glass epoxy substrate of the printed circuit board. When the copper thickness is ≥ 20z, it is defined as thick copper board. In PCB proofing, thick copper plate is a special process, which has certain technical threshold and operation difficulty, and the cost is relatively expensive. area. Thick copper plates are widely used in various household appliances, high-tech products, medical and other electronic equipment.

Why use thick copper circuit board?

Rigid-flex PCB contain more than three ounces of copper material per square foot and are used to carry high current loads. You will find copper material thicknesses used in such PCBs in the range of 105 – 400 µm. Additionally, Rigid-flex PCB are able to maintain dissipation at high temperatures while providing stronger connections. Additionally, this thermal management feature ensures that thick copper PCBs are free from thermal stress.

What are the performance and advantages of Rigid-flex PCB?

A Rigid-flex PCB is a layer of copper foil bonded to the glass epoxy substrate of the printed circuit board. The thickness of this copper foil can be divided into many different types, such as 18um, 35um, 55um and 70um. The thickness varies. The applications are also very different. Rigid-flex PCB plates are mainly used in power-saving products, especially electronic products that require higher voltage and current. So what are the advantages and performance of Rigid-flex PCB?

- Rigid-flex PCB have a wide range of applications and are used in almost all metal materials used in construction. Thick copper sheets have the best elongation properties and are ideal for architectural moldings. Rigid-flex PCB are not limited by processing temperatures. It can blow oxygen at high melting point, but not brittle at low temperature. It is also fireproof and is a non-combustible material. Copper PCBs form a strong, non-toxic bell-like protective layer even in highly corrosive atmospheres.

- Unique advantages of thick copper pcb circuit board: Rigid-flex PCB not only has excellent strength and processing adaptability, but also can be applied to various processes, such as unit wall, flat lock system, standing edge snap system, Bem system, rainwater drainage system etc. It can also accommodate the various processing requirements these systems require and, since Rigid-flex PCB boards are affordable, they are often sold at hardware stores. Affordable thick copper printed circuit boards are not only used in industrial buildings, even in life, workers who understand electrical technology can purchase and modify them as needed.

- The application of Rigid-flex PCB is almost everywhere, and its application fields are very wide, including various household appliances, high-tech products, military, medical and other electronic equipment. The application of thick-hole copper plate makes the circuit board of electronic equipment products have a longer service life, and at the same time greatly helps to simplify the size of electronic equipment. Today, the number of manufacturers producing Rigid-flex PCB in the market is gradually increasing.

Why Choose HSX

Top Rigid-flex PCB plate material resources, so that your products win at the root

The factory always has imported and domestic plates

- The processing substrate material of the flexible and rigid board is the same as the flexible circuit board, which is also a flexible copper clad laminate FCCL (Flexible Copper Clad Laminate). FCCL refers to a copper-clad laminate formed by bonding one or both sides of flexible insulating materials such as polyimide film or polyester film with copper foil through a certain process.

Leading process capability to meet Rigid-flex PCB manufacturing needs

- Max. thickness to diameter ratio 10:1 Max. copper thickness 6OZ Max. working board size 2000x610mm

- The thinnest 4-layer board 0.33mm The smallest hole 0.10mm

- Minimum line width/line spacing 3mil/3mil

- Proven hybrid technology: ROGERS/Rogers+FR4,FR4+PTFE,FR4+408HR,ceramic+FR4 etc.

Experienced

- PCB Rigid-flex PCB samples + small and medium batch, more than ten years of experience, skilled in PCB Rigid-flex PCB expertise

- Products are: FR4 glass fiber board double-sided multilayer circuit board / Rigid-flex PCB board / Rigid-flex PCB board / Rigid-flex PCB mixed laminate / mixed media laminate / F4B Rigid-flex PCB board / microwave RF board / Rigid-flex PCB microwave board, etc., the power splitter, coupler, combiner, power amplifier, dry amplifier, base station, RF antenna, 4G antenna used in the Rigid-flex PCB has professional production experience

PCB acceptance criteria

- IPC-A-600G standard (PCB conformity standard);

- GJB326A-96(military standard);

- IPC-6018A (Rigid-flex PCB acceptance standards)

- Implementation of quality PDCA cycle process, continuous improvement of product performance imported from the United States Diane ion chromatography tester (DIONEXICS-900) and temperature cycle inspection equipment to ensure high reliability and stability of the product.

Why Choose HSX

Top high-frequency material resources, so that your products win at the root

The factory always has imported and domestic plates with dielectric constants ranging from 2.2 to 10.6

- High frequency materials: Rogers/Rogers, taconic/taikangli, Arlon, Isola, F4BM/Wangling, PTFE/Teflon, TP-2, etc., with dielectric constants ranging from 2.2 to 10.6.

- Rogers series: Rogers RO4350B, RO4003C, RT5880, RT5870, ro3003, ro3010, RO4730, RT6006, RT6010, etc.

Leading process capability to meet high frequency PCB manufacturing needs

- Max. thickness to diameter ratio 10:1 Max. copper thickness 6OZ Max. working board size 2000x610mm

- The thinnest 4-layer board 0.33mm The smallest hole 0.10mm

- Minimum line width/line spacing 3mil/3mil

- Proven hybrid technology: ROGERS/Rogers+FR4,FR4+PTFE,FR4+408HR,ceramic+FR4 etc.

Experienced

PCB high-frequency board samples + small and medium batch, more than ten years of experience, skilled in PCB high-frequency board expertise

Products are: FR4 glass fiber board double-sided multilayer circuit board / high frequency board / high frequency circuit board / high frequency mixed laminate / mixed media laminate / F4B high frequency board / microwave RF board / high frequency microwave board, etc., the power splitter, coupler, combiner, power amplifier, dry amplifier, base station, RF antenna, 4G antenna used in the high frequency circuit board has professional production experience

PCB acceptance criteria

- IPC-A-600G standard (PCB conformity standard);

- GJB326A-96(military standard);

- IPC-6018A (high frequency board acceptance standards)

- Implementation of quality PDCA cycle process, continuous improvement of product performance imported from the United States Diane ion chromatography tester (DIONEXICS-900) and temperature cycle inspection equipment to ensure high reliability and stability of the product.

HSX’s Rigid-flex PCB Capabilities

Feature

Capability

Quality Grade

Standard IPC 2

Number of Layers

2- 24layers

Material

ROGERS, TACONIC, ARLON, FR4,

Board Size

Min 5mm x 5mm | Max 500mm x 745mm

Board Thickness

0.2mm – 4.0mm

Copper Weight(Finished)

0.5oz – 2oz

Min Tracing/Spacing

3mil/3mil

Solder Mask Color

Green, White, Blue, Black, Red, Yellow…

Silkscreen Color

White, Black, Yellow…

Surface Finish

Electroless nickel/immersion gold (ENIG) – RoHS

Immersion silver – RoHS

Immersion tin – RoHS

Min Annular Ring

0.1mm

Min Drilling Hole Diameter

0.15mm

Other Techniques

Peelable solder mask

Gold fingers

Carbon oil

Countersink holes

Do You Need Assistance or Have a Question?

We Provide Quality Service, Good Price for PCBs.

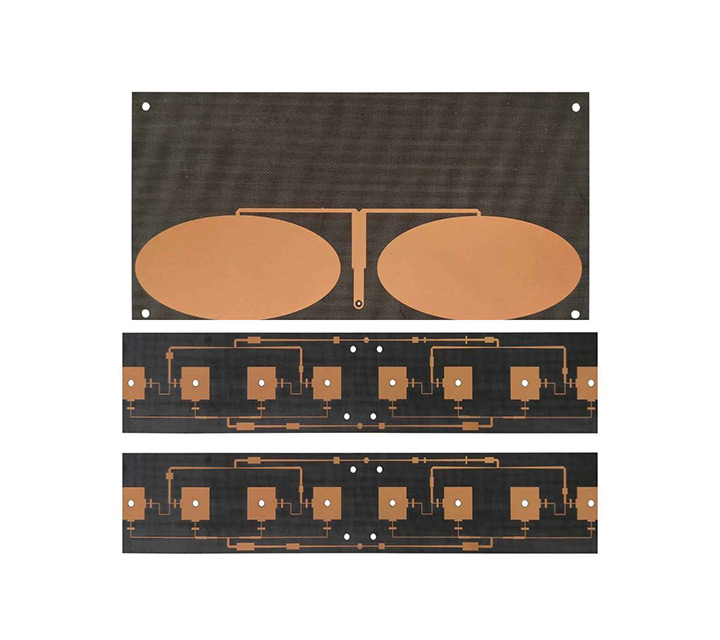

High Frequency PCB

Product Information

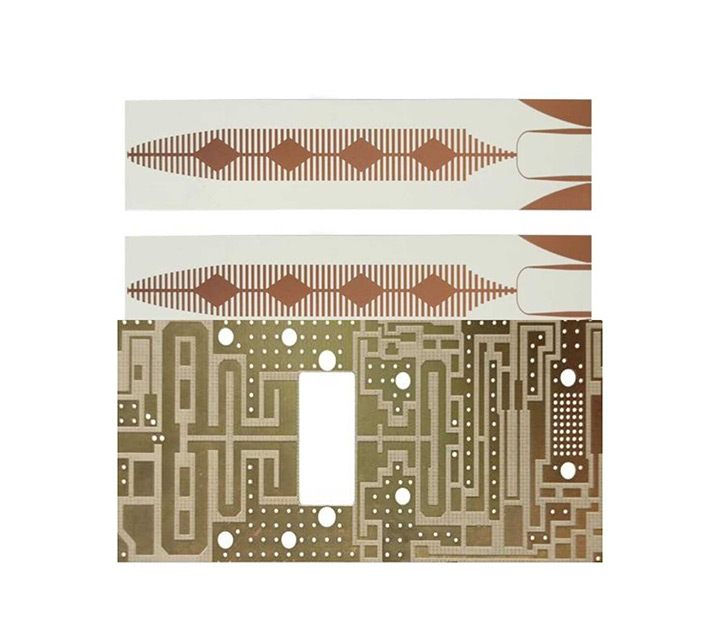

A high frequency printed circuit board, whether it’s rigid or flex, offers faster signal flow rates and a frequency range of up to 100 GHz. It’s important to note that there are numerous materials designed to operate at high frequency levels. HF PCBs are defined by lower dielectric constant (Dk), lower dissipation factor (Df), and low levels of thermal expansion. They are used regularly for HDI technology. They are also used extensively in high speed communications, telecommunications, and RF microwave technology.

Depending on the parameters, the HF signal is reflected on the circuit board, which means that the impedance (dynamic resistance) changes relative to the transmitting component. To avoid such capacitive effects, all parameters must be specified accurately and implemented with the highest level of process control.

Applications for High Frequency PCB

High frequency printed circuit boardis are widely used for special signal transmission between objects. It operates from 500MHz to 2GHz and is right for mobile, microwave, RF and high-speed design applications. With the increasing complexity of electronic components and switches, faster signal flow and better transmission frequency are needed. High frequency PCB can play a really important role.Due to the short rise time of the pulse in electronic components, it is necessary to consider the conductor width as an electronic component in HF technology.

The Necessity of Using High Frequency PCB

High-frequency PCBs usually provide a frequency range from 500MHz to 2 GHz, which can meet the needs of high-speed PCB designs, microwave, radio frequency, and mobile applications. When the frequency is above 1 GHz, we can define it as high frequency.

- The complexity of electronic components and switches is continually increasing nowadays and need faster signal flow rates. So, higher transmission frequencies are required. High-frequency PCBs help a lot when integrating special signal requirements into electronic components and products with advantages like high efficiency, and fast speed, lower attenuation, and constant dielectric properties.

- High Frequency (HF) PCB is used to transmit electromagnetic waves in the frequency of GHz with minimal loses in the variety of applications, including mobile, microwave, radio frequency (RF) and high-speed design applications. Hence, printed circuit boards with some specific characteristics are used to transmit these electromagnetic waves. Several parameters are taken into considerations while designing a PCB for high frequency applications.

- A high frequency PCB can meet your needs when incorporating a special signal requirement into your electronic devices and products. These higher transmission frequencies are capable of supporting the faster signal flow rates that are a necessity in today’s increasingly complex electronic switches and other components.

Why Choose HSX

Top high-frequency material resources, so that your products win at the root

The factory always has imported and domestic plates with dielectric constants ranging from 2.2 to 10.6

- High frequency materials: Rogers/Rogers, taconic/taikangli, Arlon, Isola, F4BM/Wangling, PTFE/Teflon, TP-2, etc., with dielectric constants ranging from 2.2 to 10.6.

- Rogers series: Rogers RO4350B, RO4003C, RT5880, RT5870, ro3003, ro3010, RO4730, RT6006, RT6010, etc.

Leading process capability to meet high frequency PCB manufacturing needs

- Max. thickness to diameter ratio 10:1 Max. copper thickness 6OZ Max. working board size 2000x610mm

- The thinnest 4-layer board 0.33mm The smallest hole 0.10mm

- Minimum line width/line spacing 3mil/3mil

- Proven hybrid technology: ROGERS/Rogers+FR4,FR4+PTFE,FR4+408HR,ceramic+FR4 etc.

Experienced

- PCB high-frequency board samples + small and medium batch, more than ten years of experience, skilled in PCB high-frequency board expertise

- Products are: FR4 glass fiber board double-sided multilayer circuit board / high frequency board / high frequency circuit board / high frequency mixed laminate / mixed media laminate / F4B high frequency board / microwave RF board / high frequency microwave board, etc., the power splitter, coupler, combiner, power amplifier, dry amplifier, base station, RF antenna, 4G antenna used in the high frequency circuit board has professional production experience

PCB acceptance criteria

- IPC-A-600G standard (PCB conformity standard);

- GJB326A-96(military standard);

- IPC-6018A (high frequency board acceptance standards)

- Implementation of quality PDCA cycle process, continuous improvement of product performance imported from the United States Diane ion chromatography tester (DIONEXICS-900) and temperature cycle inspection equipment to ensure high reliability and stability of the product.

Why Choose HSX

Top high-frequency material resources, so that your products win at the root

The factory always has imported and domestic plates with dielectric constants ranging from 2.2 to 10.6

- High frequency materials: Rogers/Rogers, taconic/taikangli, Arlon, Isola, F4BM/Wangling, PTFE/Teflon, TP-2, etc., with dielectric constants ranging from 2.2 to 10.6.

- Rogers series: Rogers RO4350B, RO4003C, RT5880, RT5870, ro3003, ro3010, RO4730, RT6006, RT6010, etc.

Leading process capability to meet high frequency PCB manufacturing needs

- Max. thickness to diameter ratio 10:1 Max. copper thickness 6OZ Max. working board size 2000x610mm

- The thinnest 4-layer board 0.33mm The smallest hole 0.10mm

- Minimum line width/line spacing 3mil/3mil

- Proven hybrid technology: ROGERS/Rogers+FR4,FR4+PTFE,FR4+408HR,ceramic+FR4 etc.

Experienced

PCB high-frequency board samples + small and medium batch, more than ten years of experience, skilled in PCB high-frequency board expertise

Products are: FR4 glass fiber board double-sided multilayer circuit board / high frequency board / high frequency circuit board / high frequency mixed laminate / mixed media laminate / F4B high frequency board / microwave RF board / high frequency microwave board, etc., the power splitter, coupler, combiner, power amplifier, dry amplifier, base station, RF antenna, 4G antenna used in the high frequency circuit board has professional production experience

PCB acceptance criteria

- IPC-A-600G standard (PCB conformity standard);

- GJB326A-96(military standard);

- IPC-6018A (high frequency board acceptance standards)

- Implementation of quality PDCA cycle process, continuous improvement of product performance imported from the United States Diane ion chromatography tester (DIONEXICS-900) and temperature cycle inspection equipment to ensure high reliability and stability of the product.

HSX’s High Frequency PCB Capabilities

Feature

Capability

Quality Grade

Standard IPC 2

Number of Layers

2- 24layers

Material

ROGERS, TACONIC, ARLON, FR4,

Board Size

Min 5mm x 5mm | Max 500mm x 745mm

Board Thickness

0.2mm – 4.0mm

Copper Weight(Finished)

0.5oz – 2oz

Min Tracing/Spacing

3mil/3mil

Solder Mask Color

Green, White, Blue, Black, Red, Yellow…

Silkscreen Color

White, Black, Yellow…

Surface Finish

Electroless nickel/immersion gold (ENIG) – RoHS

Immersion silver – RoHS

Immersion tin – RoHS

Min Annular Ring

0.1mm

Min Drilling Hole Diameter

0.15mm

Other Techniques

Peelable solder mask

Gold fingers

Carbon oil

Countersink holes

Do You Need Assistance or Have a Question?

We Provide Quality Service, Good Price for PCBs.

High Frequency PCB

Product Information

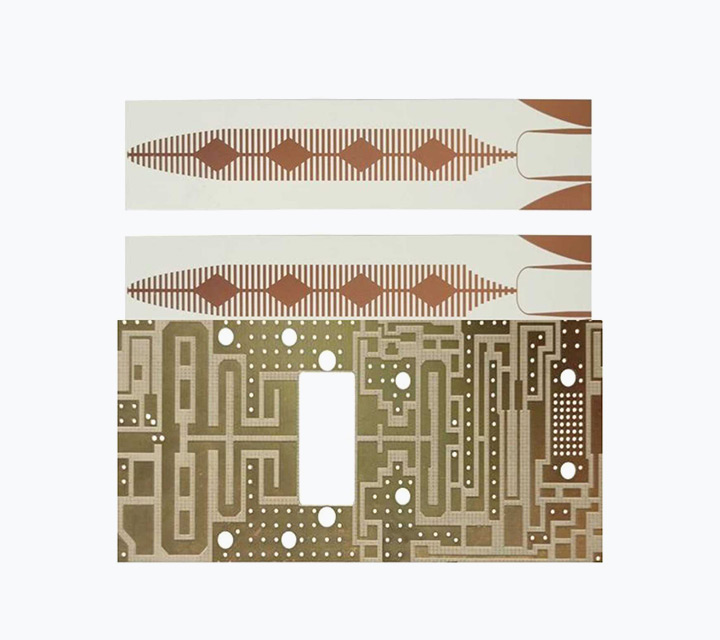

A high frequency printed circuit board, whether it’s rigid or flex, offers faster signal flow rates and a frequency range of up to 100 GHz. It’s important to note that there are numerous materials designed to operate at high frequency levels. HF PCBs are defined by lower dielectric constant (Dk), lower dissipation factor (Df), and low levels of thermal expansion. They are used regularly for HDI technology. They are also used extensively in high speed communications, telecommunications, and RF microwave technology.

Depending on the parameters, the HF signal is reflected on the circuit board, which means that the impedance (dynamic resistance) changes relative to the transmitting component. To avoid such capacitive effects, all parameters must be specified accurately and implemented with the highest level of process control.

Applications for High Frequency PCB

High frequency printed circuit boardis are widely used for special signal transmission between objects. It operates from 500MHz to 2GHz and is right for mobile, microwave, RF and high-speed design applications. With the increasing complexity of electronic components and switches, faster signal flow and better transmission frequency are needed. High frequency PCB can play a really important role.Due to the short rise time of the pulse in electronic components, it is necessary to consider the conductor width as an electronic component in HF technology.

The Necessity of Using High Frequency PCB

High-frequency PCBs usually provide a frequency range from 500MHz to 2 GHz, which can meet the needs of high-speed PCB designs, microwave, radio frequency, and mobile applications. When the frequency is above 1 GHz, we can define it as high frequency.

- The complexity of electronic components and switches is continually increasing nowadays and need faster signal flow rates. So, higher transmission frequencies are required. High-frequency PCBs help a lot when integrating special signal requirements into electronic components and products with advantages like high efficiency, and fast speed, lower attenuation, and constant dielectric properties.

- High Frequency (HF) PCB is used to transmit electromagnetic waves in the frequency of GHz with minimal loses in the variety of applications, including mobile, microwave, radio frequency (RF) and high-speed design applications. Hence, printed circuit boards with some specific characteristics are used to transmit these electromagnetic waves. Several parameters are taken into considerations while designing a PCB for high frequency applications.

- A high frequency PCB can meet your needs when incorporating a special signal requirement into your electronic devices and products. These higher transmission frequencies are capable of supporting the faster signal flow rates that are a necessity in today’s increasingly complex electronic switches and other components.

Why Choose HSX

Top high-frequency material resources, so that your products win at the root

The factory always has imported and domestic plates with dielectric constants ranging from 2.2 to 10.6

- High frequency materials: Rogers/Rogers, taconic/taikangli, Arlon, Isola, F4BM/Wangling, PTFE/Teflon, TP-2, etc., with dielectric constants ranging from 2.2 to 10.6.

- Rogers series: Rogers RO4350B, RO4003C, RT5880, RT5870, ro3003, ro3010, RO4730, RT6006, RT6010, etc.

Leading process capability to meet high frequency PCB manufacturing needs

- Max. thickness to diameter ratio 10:1 Max. copper thickness 6OZ Max. working board size 2000x610mm

- The thinnest 4-layer board 0.33mm The smallest hole 0.10mm

- Minimum line width/line spacing 3mil/3mil

- Proven hybrid technology: ROGERS/Rogers+FR4,FR4+PTFE,FR4+408HR,ceramic+FR4 etc.

Experienced

- PCB high-frequency board samples + small and medium batch, more than ten years of experience, skilled in PCB high-frequency board expertise

- Products are: FR4 glass fiber board double-sided multilayer circuit board / high frequency board / high frequency circuit board / high frequency mixed laminate / mixed media laminate / F4B high frequency board / microwave RF board / high frequency microwave board, etc., the power splitter, coupler, combiner, power amplifier, dry amplifier, base station, RF antenna, 4G antenna used in the high frequency circuit board has professional production experience

PCB acceptance criteria

- IPC-A-600G standard (PCB conformity standard);

- GJB326A-96(military standard);

- IPC-6018A (high frequency board acceptance standards)

- Implementation of quality PDCA cycle process, continuous improvement of product performance imported from the United States Diane ion chromatography tester (DIONEXICS-900) and temperature cycle inspection equipment to ensure high reliability and stability of the product.

Why Choose HSX

Top high-frequency material resources, so that your products win at the root

The factory always has imported and domestic plates with dielectric constants ranging from 2.2 to 10.6

- High frequency materials: Rogers/Rogers, taconic/taikangli, Arlon, Isola, F4BM/Wangling, PTFE/Teflon, TP-2, etc., with dielectric constants ranging from 2.2 to 10.6.

- Rogers series: Rogers RO4350B, RO4003C, RT5880, RT5870, ro3003, ro3010, RO4730, RT6006, RT6010, etc.

Leading process capability to meet high frequency PCB manufacturing needs

- Max. thickness to diameter ratio 10:1 Max. copper thickness 6OZ Max. working board size 2000x610mm

- The thinnest 4-layer board 0.33mm The smallest hole 0.10mm

- Minimum line width/line spacing 3mil/3mil

- Proven hybrid technology: ROGERS/Rogers+FR4,FR4+PTFE,FR4+408HR,ceramic+FR4 etc.

Experienced

PCB high-frequency board samples + small and medium batch, more than ten years of experience, skilled in PCB high-frequency board expertise

Products are: FR4 glass fiber board double-sided multilayer circuit board / high frequency board / high frequency circuit board / high frequency mixed laminate / mixed media laminate / F4B high frequency board / microwave RF board / high frequency microwave board, etc., the power splitter, coupler, combiner, power amplifier, dry amplifier, base station, RF antenna, 4G antenna used in the high frequency circuit board has professional production experience

PCB acceptance criteria

- IPC-A-600G standard (PCB conformity standard);

- GJB326A-96(military standard);

- IPC-6018A (high frequency board acceptance standards)

- Implementation of quality PDCA cycle process, continuous improvement of product performance imported from the United States Diane ion chromatography tester (DIONEXICS-900) and temperature cycle inspection equipment to ensure high reliability and stability of the product.

HSX’s High Frequency PCB Capabilities

Feature

Capability

Quality Grade

Standard IPC 2

Number of Layers

2- 24layers

Material

ROGERS, TACONIC, ARLON, FR4,

Board Size

Min 5mm x 5mm | Max 500mm x 745mm

Board Thickness

0.2mm – 4.0mm

Copper Weight(Finished)

0.5oz – 2oz

Min Tracing/Spacing

3mil/3mil

Solder Mask Color

Green, White, Blue, Black, Red, Yellow…

Silkscreen Color

White, Black, Yellow…

Surface Finish

Electroless nickel/immersion gold (ENIG) – RoHS

Immersion silver – RoHS

Immersion tin – RoHS

Min Annular Ring

0.1mm

Min Drilling Hole Diameter

0.15mm

Other Techniques

Peelable solder mask

Gold fingers

Carbon oil

Countersink holes

Do You Need Assistance or Have a Question?

We Provide Quality Service, Good Price for PCBs.

High Frequency PCB

Product Information

A high frequency printed circuit board, whether it’s rigid or flex, offers faster signal flow rates and a frequency range of up to 100 GHz. It’s important to note that there are numerous materials designed to operate at high frequency levels. HF PCBs are defined by lower dielectric constant (Dk), lower dissipation factor (Df), and low levels of thermal expansion. They are used regularly for HDI technology. They are also used extensively in high speed communications, telecommunications, and RF microwave technology.

Depending on the parameters, the HF signal is reflected on the circuit board, which means that the impedance (dynamic resistance) changes relative to the transmitting component. To avoid such capacitive effects, all parameters must be specified accurately and implemented with the highest level of process control.

Applications for High Frequency PCB

High frequency printed circuit boardis are widely used for special signal transmission between objects. It operates from 500MHz to 2GHz and is right for mobile, microwave, RF and high-speed design applications. With the increasing complexity of electronic components and switches, faster signal flow and better transmission frequency are needed. High frequency PCB can play a really important role.Due to the short rise time of the pulse in electronic components, it is necessary to consider the conductor width as an electronic component in HF technology.

The Necessity of Using High Frequency PCB

High-frequency PCBs usually provide a frequency range from 500MHz to 2 GHz, which can meet the needs of high-speed PCB designs, microwave, radio frequency, and mobile applications. When the frequency is above 1 GHz, we can define it as high frequency.

- The complexity of electronic components and switches is continually increasing nowadays and need faster signal flow rates. So, higher transmission frequencies are required. High-frequency PCBs help a lot when integrating special signal requirements into electronic components and products with advantages like high efficiency, and fast speed, lower attenuation, and constant dielectric properties.

- High Frequency (HF) PCB is used to transmit electromagnetic waves in the frequency of GHz with minimal loses in the variety of applications, including mobile, microwave, radio frequency (RF) and high-speed design applications. Hence, printed circuit boards with some specific characteristics are used to transmit these electromagnetic waves. Several parameters are taken into considerations while designing a PCB for high frequency applications.

- A high frequency PCB can meet your needs when incorporating a special signal requirement into your electronic devices and products. These higher transmission frequencies are capable of supporting the faster signal flow rates that are a necessity in today’s increasingly complex electronic switches and other components.

Why Choose HSX

Top high-frequency material resources, so that your products win at the root

The factory always has imported and domestic plates with dielectric constants ranging from 2.2 to 10.6

- High frequency materials: Rogers/Rogers, taconic/taikangli, Arlon, Isola, F4BM/Wangling, PTFE/Teflon, TP-2, etc., with dielectric constants ranging from 2.2 to 10.6.

- Rogers series: Rogers RO4350B, RO4003C, RT5880, RT5870, ro3003, ro3010, RO4730, RT6006, RT6010, etc.

Leading process capability to meet high frequency PCB manufacturing needs

- Max. thickness to diameter ratio 10:1 Max. copper thickness 6OZ Max. working board size 2000x610mm

- The thinnest 4-layer board 0.33mm The smallest hole 0.10mm

- Minimum line width/line spacing 3mil/3mil

- Proven hybrid technology: ROGERS/Rogers+FR4,FR4+PTFE,FR4+408HR,ceramic+FR4 etc.

Experienced

- PCB high-frequency board samples + small and medium batch, more than ten years of experience, skilled in PCB high-frequency board expertise

- Products are: FR4 glass fiber board double-sided multilayer circuit board / high frequency board / high frequency circuit board / high frequency mixed laminate / mixed media laminate / F4B high frequency board / microwave RF board / high frequency microwave board, etc., the power splitter, coupler, combiner, power amplifier, dry amplifier, base station, RF antenna, 4G antenna used in the high frequency circuit board has professional production experience

PCB acceptance criteria

- IPC-A-600G standard (PCB conformity standard);

- GJB326A-96(military standard);

- IPC-6018A (high frequency board acceptance standards)

- Implementation of quality PDCA cycle process, continuous improvement of product performance imported from the United States Diane ion chromatography tester (DIONEXICS-900) and temperature cycle inspection equipment to ensure high reliability and stability of the product.

Why Choose HSX

Top high-frequency material resources, so that your products win at the root

The factory always has imported and domestic plates with dielectric constants ranging from 2.2 to 10.6

- High frequency materials: Rogers/Rogers, taconic/taikangli, Arlon, Isola, F4BM/Wangling, PTFE/Teflon, TP-2, etc., with dielectric constants ranging from 2.2 to 10.6.

- Rogers series: Rogers RO4350B, RO4003C, RT5880, RT5870, ro3003, ro3010, RO4730, RT6006, RT6010, etc.

Leading process capability to meet high frequency PCB manufacturing needs

- Max. thickness to diameter ratio 10:1 Max. copper thickness 6OZ Max. working board size 2000x610mm

- The thinnest 4-layer board 0.33mm The smallest hole 0.10mm

- Minimum line width/line spacing 3mil/3mil

- Proven hybrid technology: ROGERS/Rogers+FR4,FR4+PTFE,FR4+408HR,ceramic+FR4 etc.

Experienced

PCB high-frequency board samples + small and medium batch, more than ten years of experience, skilled in PCB high-frequency board expertise

Products are: FR4 glass fiber board double-sided multilayer circuit board / high frequency board / high frequency circuit board / high frequency mixed laminate / mixed media laminate / F4B high frequency board / microwave RF board / high frequency microwave board, etc., the power splitter, coupler, combiner, power amplifier, dry amplifier, base station, RF antenna, 4G antenna used in the high frequency circuit board has professional production experience

PCB acceptance criteria

- IPC-A-600G standard (PCB conformity standard);

- GJB326A-96(military standard);

- IPC-6018A (high frequency board acceptance standards)

- Implementation of quality PDCA cycle process, continuous improvement of product performance imported from the United States Diane ion chromatography tester (DIONEXICS-900) and temperature cycle inspection equipment to ensure high reliability and stability of the product.

HSX’s High Frequency PCB Capabilities

Feature

Capability

Quality Grade

Standard IPC 2

Number of Layers

2- 24layers

Material

ROGERS, TACONIC, ARLON, FR4,

Board Size

Min 5mm x 5mm | Max 500mm x 745mm

Board Thickness

0.2mm – 4.0mm

Copper Weight(Finished)

0.5oz – 2oz

Min Tracing/Spacing

3mil/3mil

Solder Mask Color

Green, White, Blue, Black, Red, Yellow…

Silkscreen Color

White, Black, Yellow…

Surface Finish

Electroless nickel/immersion gold (ENIG) – RoHS

Immersion silver – RoHS

Immersion tin – RoHS

Min Annular Ring

0.1mm

Min Drilling Hole Diameter

0.15mm

Other Techniques

Peelable solder mask

Gold fingers

Carbon oil

Countersink holes

Do You Need Assistance or Have a Question?

We Provide Quality Service, Good Price for PCBs.

High Frequency PCB

Product Information

A high frequency printed circuit board, whether it’s rigid or flex, offers faster signal flow rates and a frequency range of up to 100 GHz. It’s important to note that there are numerous materials designed to operate at high frequency levels. HF PCBs are defined by lower dielectric constant (Dk), lower dissipation factor (Df), and low levels of thermal expansion. They are used regularly for HDI technology. They are also used extensively in high speed communications, telecommunications, and RF microwave technology.

Depending on the parameters, the HF signal is reflected on the circuit board, which means that the impedance (dynamic resistance) changes relative to the transmitting component. To avoid such capacitive effects, all parameters must be specified accurately and implemented with the highest level of process control.

Applications for High Frequency PCB

High frequency printed circuit boardis are widely used for special signal transmission between objects. It operates from 500MHz to 2GHz and is right for mobile, microwave, RF and high-speed design applications. With the increasing complexity of electronic components and switches, faster signal flow and better transmission frequency are needed. High frequency PCB can play a really important role.Due to the short rise time of the pulse in electronic components, it is necessary to consider the conductor width as an electronic component in HF technology.

The Necessity of Using High Frequency PCB

High-frequency PCBs usually provide a frequency range from 500MHz to 2 GHz, which can meet the needs of high-speed PCB designs, microwave, radio frequency, and mobile applications. When the frequency is above 1 GHz, we can define it as high frequency.

- The complexity of electronic components and switches is continually increasing nowadays and need faster signal flow rates. So, higher transmission frequencies are required. High-frequency PCBs help a lot when integrating special signal requirements into electronic components and products with advantages like high efficiency, and fast speed, lower attenuation, and constant dielectric properties.

- High Frequency (HF) PCB is used to transmit electromagnetic waves in the frequency of GHz with minimal loses in the variety of applications, including mobile, microwave, radio frequency (RF) and high-speed design applications. Hence, printed circuit boards with some specific characteristics are used to transmit these electromagnetic waves. Several parameters are taken into considerations while designing a PCB for high frequency applications.

- A high frequency PCB can meet your needs when incorporating a special signal requirement into your electronic devices and products. These higher transmission frequencies are capable of supporting the faster signal flow rates that are a necessity in today’s increasingly complex electronic switches and other components.

Why Choose HSX

Top high-frequency material resources, so that your products win at the root

The factory always has imported and domestic plates with dielectric constants ranging from 2.2 to 10.6

- High frequency materials: Rogers/Rogers, taconic/taikangli, Arlon, Isola, F4BM/Wangling, PTFE/Teflon, TP-2, etc., with dielectric constants ranging from 2.2 to 10.6.

- Rogers series: Rogers RO4350B, RO4003C, RT5880, RT5870, ro3003, ro3010, RO4730, RT6006, RT6010, etc.

Leading process capability to meet high frequency PCB manufacturing needs

- Max. thickness to diameter ratio 10:1 Max. copper thickness 6OZ Max. working board size 2000x610mm

- The thinnest 4-layer board 0.33mm The smallest hole 0.10mm

- Minimum line width/line spacing 3mil/3mil

- Proven hybrid technology: ROGERS/Rogers+FR4,FR4+PTFE,FR4+408HR,ceramic+FR4 etc.

Experienced

- PCB high-frequency board samples + small and medium batch, more than ten years of experience, skilled in PCB high-frequency board expertise

- Products are: FR4 glass fiber board double-sided multilayer circuit board / high frequency board / high frequency circuit board / high frequency mixed laminate / mixed media laminate / F4B high frequency board / microwave RF board / high frequency microwave board, etc., the power splitter, coupler, combiner, power amplifier, dry amplifier, base station, RF antenna, 4G antenna used in the high frequency circuit board has professional production experience

PCB acceptance criteria

- IPC-A-600G standard (PCB conformity standard);

- GJB326A-96(military standard);

- IPC-6018A (high frequency board acceptance standards)

- Implementation of quality PDCA cycle process, continuous improvement of product performance imported from the United States Diane ion chromatography tester (DIONEXICS-900) and temperature cycle inspection equipment to ensure high reliability and stability of the product.

Why Choose HSX

Top high-frequency material resources, so that your products win at the root

The factory always has imported and domestic plates with dielectric constants ranging from 2.2 to 10.6

- High frequency materials: Rogers/Rogers, taconic/taikangli, Arlon, Isola, F4BM/Wangling, PTFE/Teflon, TP-2, etc., with dielectric constants ranging from 2.2 to 10.6.

- Rogers series: Rogers RO4350B, RO4003C, RT5880, RT5870, ro3003, ro3010, RO4730, RT6006, RT6010, etc.

Leading process capability to meet high frequency PCB manufacturing needs

- Max. thickness to diameter ratio 10:1 Max. copper thickness 6OZ Max. working board size 2000x610mm

- The thinnest 4-layer board 0.33mm The smallest hole 0.10mm

- Minimum line width/line spacing 3mil/3mil

- Proven hybrid technology: ROGERS/Rogers+FR4,FR4+PTFE,FR4+408HR,ceramic+FR4 etc.

Experienced

PCB high-frequency board samples + small and medium batch, more than ten years of experience, skilled in PCB high-frequency board expertise

Products are: FR4 glass fiber board double-sided multilayer circuit board / high frequency board / high frequency circuit board / high frequency mixed laminate / mixed media laminate / F4B high frequency board / microwave RF board / high frequency microwave board, etc., the power splitter, coupler, combiner, power amplifier, dry amplifier, base station, RF antenna, 4G antenna used in the high frequency circuit board has professional production experience

PCB acceptance criteria

- IPC-A-600G standard (PCB conformity standard);

- GJB326A-96(military standard);

- IPC-6018A (high frequency board acceptance standards)

- Implementation of quality PDCA cycle process, continuous improvement of product performance imported from the United States Diane ion chromatography tester (DIONEXICS-900) and temperature cycle inspection equipment to ensure high reliability and stability of the product.